Add to Enquiry Bag

Enquire NowTrue diameter of the hole is picked up on the taper and the center will be punched in the true position.

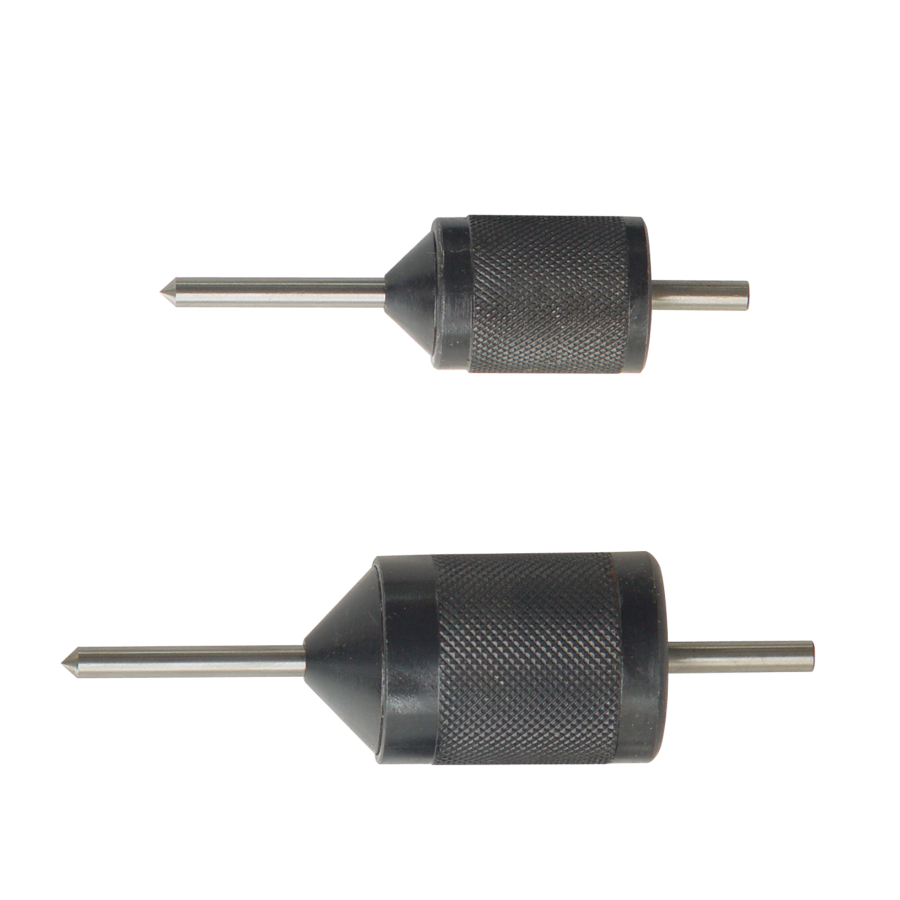

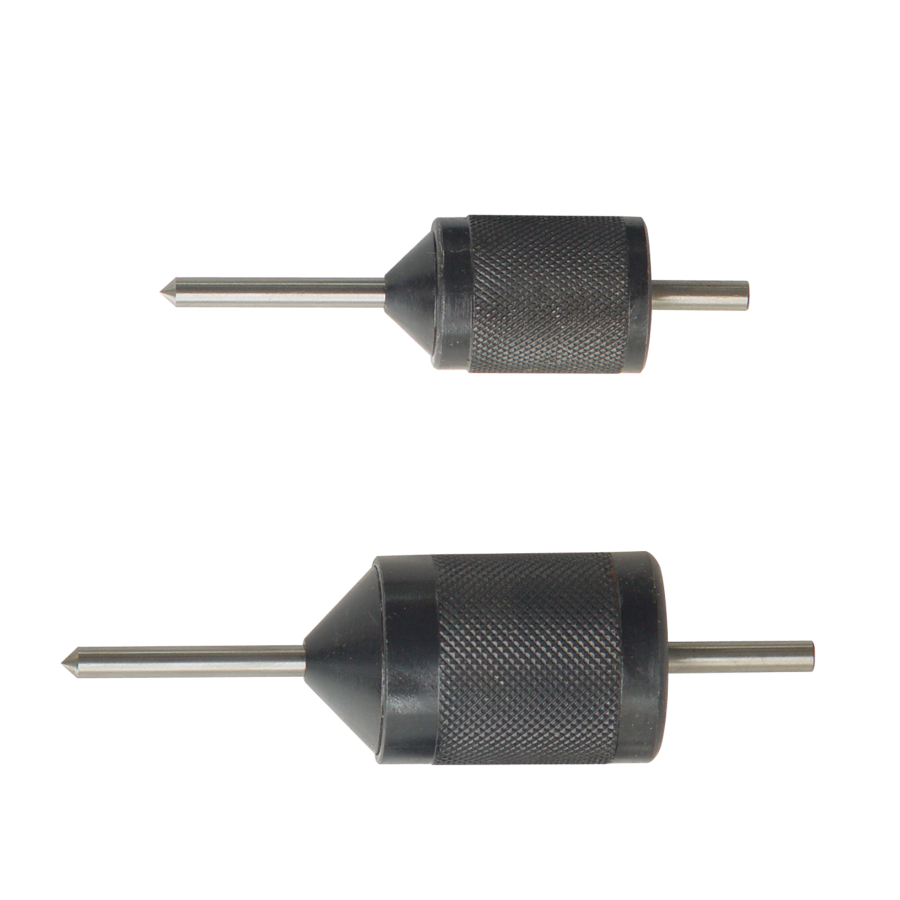

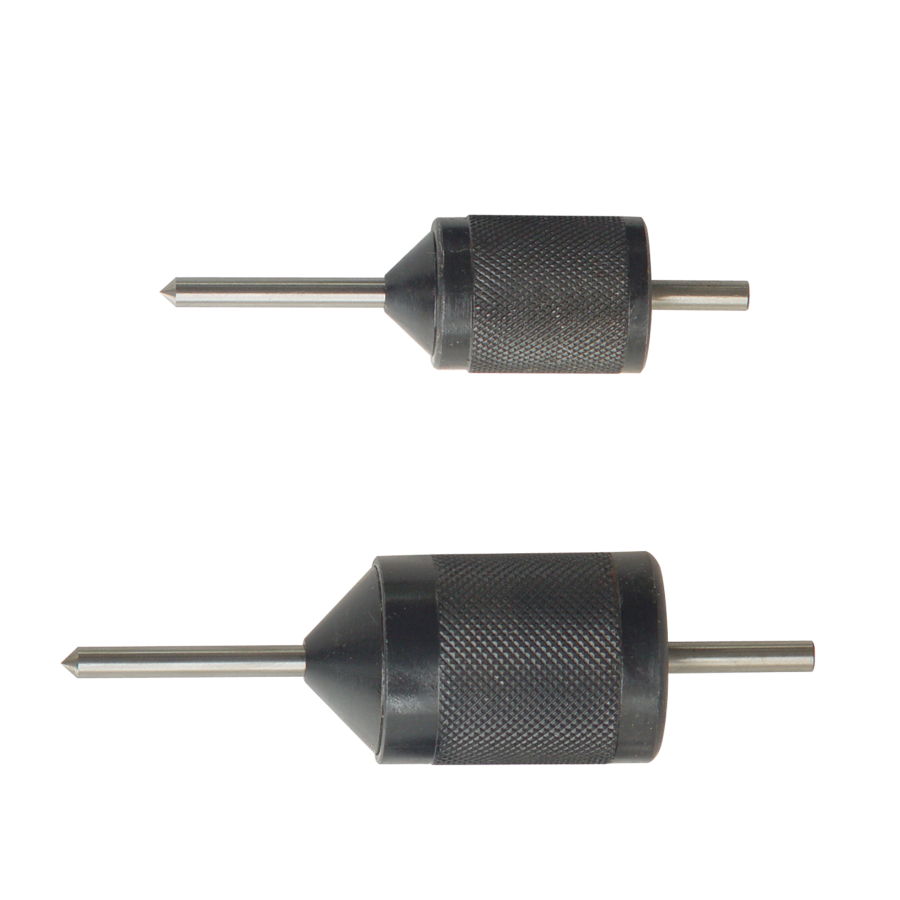

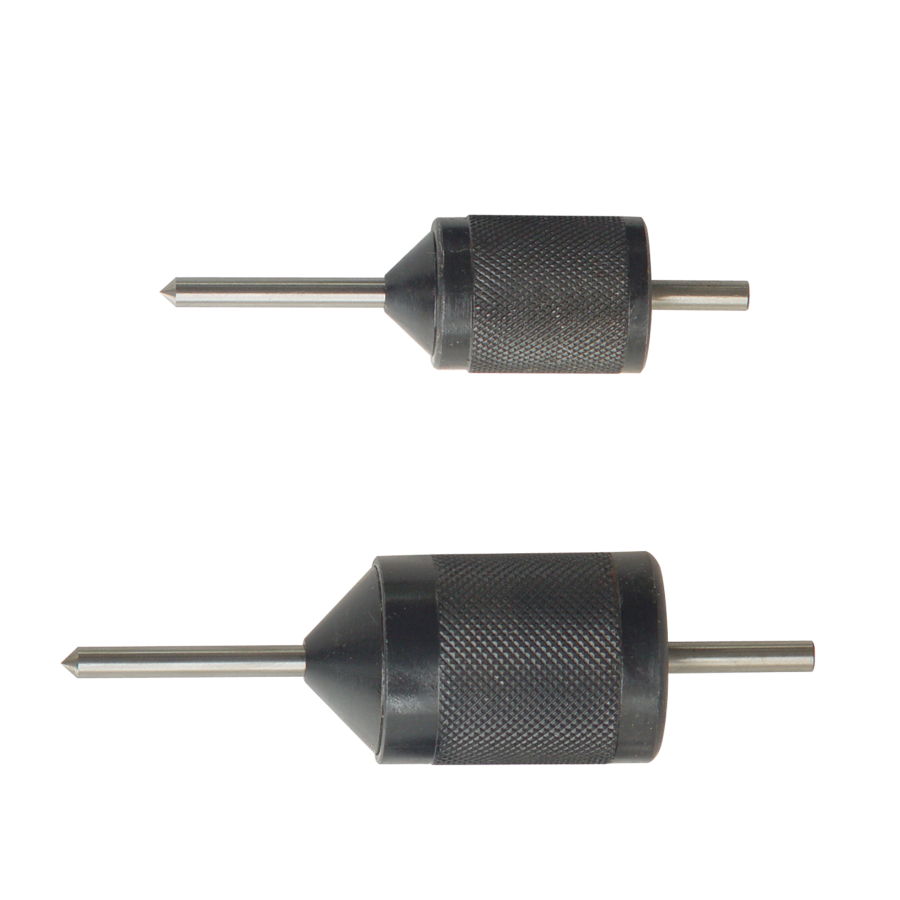

Hardened guide cone is placed into the clean edge of the hole to be transferred. Spring loaded knurled body is pushed against the face of the workpiece, perpendicular to the center line of the hole.

Transferring hole centres using a template with varying hole sizes

| Ordering | Size | Minimum | Maximum | Size | Wt. | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. | Hole Size | Hole Size | Pin | Spring loded | Body Dia | Body Length | Kg. | |||||

| Inch | mm | Inch | mm | Inch | mm | Inch | mm | |||||

| 181500 | Small | 6mm (1/4") | 16mm (5/8") | 3/16 x 3.1/2 | 5 x 90 | 3/4 | 19 | 15/16 | 24 | 1.1/4 | 32 | 0.100 |

| 181510 | Large | 10mm(3/8") | 25mm(1") | 3/16 x 4.1/2 | 5 x 113 | 1 | 26 | 1.1/4 | 32 | 1.5/8 | 42 | 0.200 |

Boring Head Kits

Precision Milling Machine Vises

Precision Tilting and Swiveling Machine Vises

Checkout our latest

Product Catalogues